Contributing writers: Kaliappa Ragunathan and Punit Thakkar, BASF

Corporation

Previously published in CoatingsTech magazine, February 2018.

Architectural exterior coatings are subject to very harsh environmental elements. Extreme conditions like cold and

hot temperatures, low and high humidity, and rain and snow test the ability of coatings to withstand cracking, limit

water absorption, prevent leaching of materials from the surface, and adhere to multiple substrates. Another

detrimental source of damage are UV rays, which induce polymer chain degradation leading to chalking and erosion of

the coatings layer. Surface coatings are also subject to dirt and mildew growth, resulting in a dirty appearance.

When designing a polymer for exterior coatings, inventors must carefully consider these destructive forces.

Professional and do-it-yourself (DIY) painters increasingly care about efficiency — that is, reducing the time

and labor involved in painting surfaces. Paints with paint-and-primer-in-one capabilities help reduce the time and

labor of painting jobs, so developing a polymer that provides both primer and topcoat properties is necessary but

also challenging. This objective further raises the performance requirement for the exterior polymer.

This study focuses on developing a polymer that addresses key needs for paint-and-primer-in-one exterior coatings,

such as dirt pick-up resistance (DPUR), leaching resistance, early rain resistance, gloss retention, grain crack

resistance, adhesion, efflorescence resistance and tannin blocking. The outcome of the study is a polymer that is

designed to withstand the exterior elements in formulations featuring <25 g/l volatile organic compounds (VOC).

Factors Impacting Critical Performance Features

Dirt Pick-Up Resistance (DPUR)

Dirt pick-up is a surface phenomenon and is mainly influenced by hardness of the coating, surface energy, surface

porosity and the nature of the dirt. Softer coating surfaces hold on to dirt better than harder surfaces; therefore,

a harder polymer is required to improve DPUR. Both highly hydrophobic and highly hydrophilic surfaces can provide

better DPUR. However, hydrophobic surfaces are preferred because hydrophilic surfaces reduce water resistance of the

coating. Hydrophobicity can be measured in terms of water contact angle — the higher the contact angle, the

better the hydrophobicity and the higher DPUR. Rough and porous surfaces tend to retain dirt better and consequently

reduce DPUR.

Conflicting Demands: Film Formation at Low VOC and DPUR

A schematic of the film formation process1,2 of emulsion polymer dispersions is depicted in three steps (Figure

1). The steps are 1) water evaporation and particle concentration, 2) particle deformation, and 3) particle

coalescence and polymer chain inter-diffusion. The degree of particle deformation and polymer chain inter-diffusion

depends on the minimum film forming temperature (MFFT) of the particles. Good film formation at low VOC requires

soft polymers or hard polymers with permanent coalescing agents. Permanent coalescing agents remain in the film

forever and reduce the hardness of the coating. Both soft polymers and hard polymers with permanent coalescing

agents lead to reduced DPUR. Thus, low VOC and better DPUR are conflicting demands and a tough problem to solve.

Leaching Resistance

Figure 3: More dirt in leached trail

Rain and dew can leach water-soluble materials from the coatings surface and create a less than desirable appearance

(Figure 2). Leaching resistance of coatings can be improved by reducing water-soluble materials, tailoring film

formation kinetics, improving early water resistance, and incorporating crosslinking chemistry. Leaching of

materials from the surface will ultimately create a porous surface, which can reduce the DPUR of the coatings.

In Figure 3, more red iron oxide adheres to the leached surface, which appears as a darker red trail.

Tannin Blocking and Efflorescence Resistance

Polyphenols (tannin) found in wood and salts in concrete/masonry substrates migrate into coatings and negatively

impact their appearance (Figures 4 and 5). Some of the factors that control these migration phenomena are

film formation kinetics, hydrophobic–hydrophilic balance of the coating, water-soluble materials, functional

groups in the polymer matrix, encapsulation of migrating materials, and adhesion of the coating to the substrate.

Figure 5: Efflorescence on concrete surface

Grain Crack Resistance

Film hardness and elasticity play a critical role in controlling the crack resistance. These two properties need to

be balanced to achieve crack resistance. Another factor that influences crack resistance is emulsion polymer

particle coalescence and film formation. Particle deformation followed by polymer chain inter-diffusion along

particle boundary (Figure 1) provide mechanical integrity to the paint film that is essential for grain crack

resistance. An example where a poorly formulated paint did not provide grain crack resistance in a southern yellow

pine board (red box) is shown in Figure 6. Other paints on the same board provide excellent grain crack

resistance.

Novel Polymer

A novel acrylic polymer was synthesized using the following design principles: particle morphology, low water-soluble

polymers and hydrophobic-hydrophilic balance. Table 1 shows the physical properties of the novel polymer

(Acronal® EDGE 4247). This polymer is free of alkyl phenol ethoxylate surfactants and can

be used to formulate <25 g/l VOC coatings.

Table 1: Novel polymer physical properties

| Property |

Value |

| Weight % solids |

52 to 54 |

| pH |

7.5 to 8.5 |

| Viscosity, cP |

<1000 |

| Particle size (volume average, nm) |

100 to 130 |

| Minimum film forming temperature |

6 to 7 |

The performance of this novel polymer was tested along with four competitive polymers (competitive latex A through

competitive latex D) in an architectural white flat coatings formulation. The formulation and its physical

characteristics are given in Tables 2 and 3, respectively. These paints were tested for topcoat and

primer properties, and the results are discussed in the following section.

Table 2: White flat formulation

| Raw Material |

Pounds |

Gallon |

| Water |

50.0 |

6.0 |

| Titanium dioxide slurry |

294.0 |

15.02 |

| Pigment dispersant |

8.0 |

0.78 |

| Defoamer |

2.0 |

0.28 |

| Wetting agent |

3.0 |

0.35 |

| Biocide |

3.0 |

0.33 |

| Inorganic filler / extender |

230.0 |

10.57 |

| Mineral thixotropic thickener |

4.0 |

0.20 |

| Grind for 20 minutes, then add: |

|

|

| Water |

155.0 |

18.61 |

| Fungicide and an algaecide |

10.0 |

1.03 |

| Neutralizing agent |

1.40 |

0.19 |

| Defoamer |

2.0 |

0.28 |

| Novel polymer (53% weight solids) |

365.0 |

41.25 |

| Polymer particle coalescing agent1 |

6.0 |

0.75 |

| Rheology modifier (high shear) |

35.0 |

4.07 |

| Rheology modifier (low shear) |

2.50 |

0.29 |

| Total |

1170.9 |

100 |

1 – Zero VOC or VOC coalescing agent

Table 3: White flat formulation physical characteristics

| Exterior Flat Formulation |

|

| VOC (gm/L) |

01 or 202 |

| Volume % solids |

41 |

| Weight % solids |

57 |

| PVC |

46 |

1 – Zero VOC coalescing agent

2 – VOC coalescing agent

Experimental

Dirt Pick-up Resistance

Paints were drawn down on a Lenetta black scrub chart using a 250-meter gap bar. The drawn down paints were cured for

24 hours at 72°F and 50 percent humidity. The cured paints were exposed to UV-A radiation for 24 hours in a UV

chamber. Then, either red iron oxide or carbon black dispersion was applied to half of the cured paint. After four

hours, the paints were gently washed with a sponge and running tap water. The washed paints were dried for 24 hours

and the Y reflectance of the soiled and unsoiled areas was measured to calculate DY reflectance.

Surfactant Leaching

Tinted paints (2% Phthalo blue) were drawn down on a Lenetta black scrub chart using a 250-meter gap bar. Tests were

done at cure times of 4 hours and 24 hours. At each cure time, three drops of water were deposited at the top of the

drawn down paints. At 10 minutes, the chart was tilted to run the water off the panel. After 24 hours, the

appearance of the water trails was rated on a 0 to 10 scale with 10 being no change and 0 being severe change.

Efflorescence Resistance

Tiles prepared from plaster of Paris were coated with a specified amount of paint leaving one inch unpainted at one

end. The paints were cured for 24 hours at 72°F and 50 percent humidity. The uncoated ends of the tiles were

placed in a sand bed soaked with 1 percent sodium sulfate solution for two weeks. Then, the appearance of the

painted end of the tiles was recorded.

Early Rain Resistance

Paints were drawn down on aluminum Q-panels using a 250-meter gap bar and dried at 72°F and 50 percent humidity

for 25 minutes. Then, the panels were placed under a 12-inch square shower head and showered for 10 minutes at

constant water flow. The appearance of the test paints was compared to the appearance of a control paint.

Tannin Blocking

Tannin blocking was tested according to ASTM 6686-1 test method. Y reflectance and yellowness index were measured,

not L* and b*.

Corrosion Resistance

Corrosion resistance was tested using cold rolled steel panels according to ASTM G85-11-A5 dilute electrolyte salt

fog test method.

Results and Discussion

Table 4 provides viscosity, film formation rating at 4°C, gloss, contrast ratio, tint strength and scrub

resistance of the coatings. The novel polymer excels in scrub resistance with 1915 scrub cycles at a PVC of 46. This

high scrub resistance indicates excellent film formation and potential for the use of this polymer for even higher

PVC coatings. Tint strength provides indirect evidence for the degree of TiO2 distribution in the coatings

matrix. The novel polymer provides the highest tint strength, while the competitive latices, except competitive

latex B, provide significantly lower tint strength. Higher tint strength indicates lower TiO2 demand to achieve

the same degree of whiteness, resulting in cost savings.

Table 4: Paint Properties

| Property |

Latex A |

Latex B |

Novel Polymer |

Latex C |

Latex D |

| Viscosity (KU) |

108.2 |

113.8 |

106.8 |

105.2 |

98.9 |

| Viscosity (ICI) |

1.6 |

1.9 |

1.4 |

1.8 |

1.6 |

| Film formation1 @ 4°C |

10 |

10 |

10 |

10 |

10 |

| Gloss 20° |

1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

| Gloss 60° |

4.2 |

4.1 |

4.1 |

4.3 |

4.1 |

| Gloss 85° |

3.2 |

3.1 |

3.0 |

3.7 |

4.0 |

| Contrast Ratio |

97.5 |

97.4 |

97.4 |

97.0 |

96.8 |

| Alkyd dry/wet adhesion, 24 hrs |

5B/5B |

5B/5B |

5B/5B |

0/0 |

5B/5B |

| Scrub resistance2 (cycles) |

1655 |

472 |

1915 |

1017 |

353 |

| Tint strength3 |

93.4 |

99.8 |

100 |

93.8 |

92.9 |

1 – 1 to 10 rating scale with 10 being perfect and 1 being

worst

2 – ASTM D 2486 test method

3 – 2% Phthalo blue tint

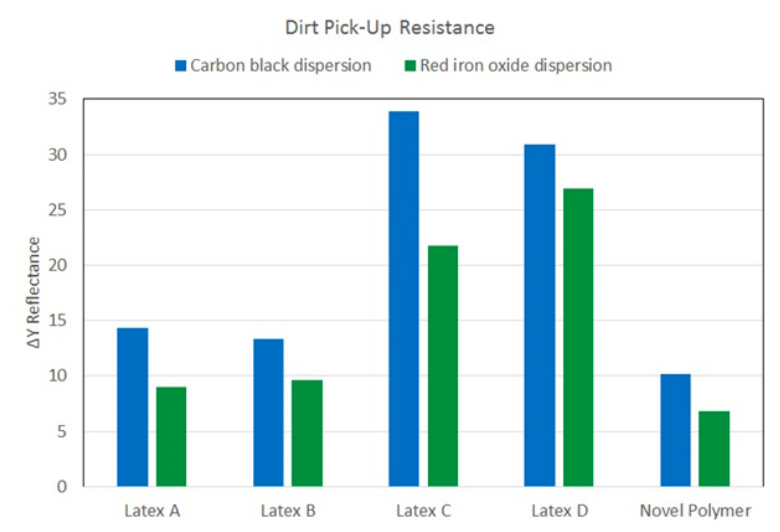

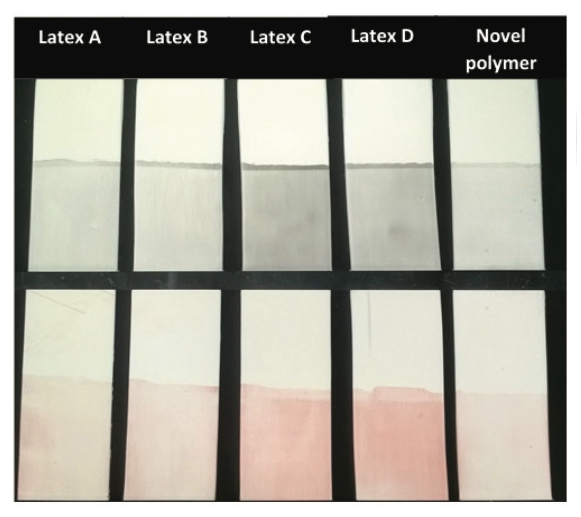

Dirt Pick-Up Resistance

Two different types of dirt — aqueous iron oxide slurry and aqueous carbon black slurry — were used to

test DPUR performance. The results are shown in Figures 7 and 8. Figure 7 shows DY

reflectance for soiled and unsoiled paint surfaces. The novel polymer has the lowest DY reflectance for both type of

dirt, indicating the best DPUR performance. Figure 8 shows the actual test panels. The novel polymer shows

the best performance from visual examination.

Figure 7: Dirt pick-up resistance

Figure 8: DPUR (carbon black and red iron oxide dispersions)

Surfactant Leaching Resistance

Leaching test results after dry times of 4 hours and 24 hours are shown in Figure 9. The novel polymer and

competitive latex A show similar performance at both dry times, but the other latices show inferior performance.

Early Rain Resistance

Early rain resistance was tested by a shower head water flow test method. The performance at 25 minutes’ dry

time of the novel polymer is compared to a leading 50 g/l VOC commercial paint. As shown in Figure

10, while the novel polymer does not exhibit any defect, the commercial paint does show defect.

Tannin Blocking

Tannin blocking of the coating is tested using Redwood and the results are shown in Figure 11. Figure

11 shows the performance in terms of DY reflectance and D yellowness of the two-coat surface. The novel polymer

has the lowest DY reflectance and D yellowness indicating the lowest amount of tannin migration to the

coating. Figure 12 shows a Redwood board with one and two coats of paint (paint and primer in one

application). The novel polymer with the second coat of the paint has the whitest appearance.

Efflorescence Resistance

The results are shown in Figure 13. The tile coated with the novel polymer-based coating does not show any salt

or defect on the surface, indicating outstanding efflorescence resistance. All other paints show copious amounts of

salt on the surface of the tile due to salt migrating through the coatings layer.

Corrosion Resistance

The novel polymer shows superior corrosion resistance along the scribe and on the surface at 250 hours of testing

(Figure 14).

Paint Film Mechanical Properties

Tensile stress and elongation play a critical role in controlling grain crack resistance. The paint film mechanical

properties for the novel polymer, competitive latex B, and a leading commercial paint are provided in Table 5.

The novel polymer has a much higher elongation without significantly compromising tensile stress. The percent of

elongation is an important feature for withstanding harsh exterior elements, including hot and cold weather and

freeze-thaw cycles.

Table 5: Mechanical properties of white flat paints

| Paint film |

Peak tensile stress (psi) |

% elongation |

| Novel Polymer |

442 |

185 |

| Competitive latex B |

584 |

69 |

| Commercial paint |

745 |

19 |

Accelerated Weathering

A semi-gloss paint formulated with novel polymer and a leading commercial paint were tested for accelerated

weathering according to the ASTM D4587-11 test method using UV-A radiation without condensation cycle. The results

are given in Figure 15 and Table 6. The novel polymer shows excellent gloss retention and minimal

color change.

Table 6: Color change ΔE in accelerated weathering study (UV A radiation)

| Hours |

Novel Polymer |

Commercial Paint |

| 250 |

0.3 |

0.4 |

| 500 |

0.9 |

0.9 |

| 1000 |

1.4 |

1.2 |

| 1500 |

1.3 |

1.3 |

To study the natural weathering of the novel polymer, southern yellow pine and cedar wood boards were coated with

flat paint formulated with the novel polymer, competitive latex 1, competitive latex 2, and a commercial paint. They

were exposed to natural weathering at a 45° angle facing south, in Charlotte, NC. The results at 36 months of

exposure are given in Table 7. The novel polymer is performing very well at 36 months of testing.

Table 7: Natural weathering results at 36 months of testing

| Paint |

Grain Cracking |

Checking |

Flaking |

Chalking* |

Dirt* |

Mildew* |

| Commercial Paint |

None |

None |

None |

9 |

8 |

8 |

| Novel Polymer |

None |

None |

None |

9 |

8 |

8 |

| Latex 1 |

None |

None |

None |

9 |

8 |

8 |

| Latex 2 |

None |

None |

None |

9 |

8 |

8 |

Summary

Architectural exterior coatings are subject to the harsh environmental elements. These harsh conditions must be

carefully considered to overcome the environment’s deleterious effects. The novel polymer developed using

innovative polymer engineering has outstanding performance for paint and primer in one exterior coatings

application. This polymer can be used to formulate <25 g/l VOC coatings. A benchmark study involving market

leading competitive binders shows (Figure 16) that the novel polymer outperforms in DPUR, leaching resistance,

tannin blocking, efflorescence resistance, scrub resistance, corrosion resistance, gloss retention, and tint

strength. Natural weathering shows excellent results at 36 months of testing.

Any questions? Contact a BASF representative to get more information or

request a sample

Get in Touch

Acknowledgments

The authors thank the following for their contributions: Scott Robinson, Shada McCurry, Jeanette Gilliam, Adam

Cummings, Kevin Kearney, Brandi Chew, Julie Adkins, Alan Smith, John Kelly, Kent Clow, Christina Nebel, Sarah

Chronister, Camilo Quiñones-Rozo, Jack Johnson, and Daniel Bates.

References

1. Yoo, J.N., Sperling, L.H., Glinka, C.J., and Klein, A., Macromolecules, 23, 3962 (1990).

2. Taylor, J.W. and Winnik, M.A., “Functional Latex and Thermoset Latex Films,” JCT

Research, (1) 3 163-190 (2004).