In the dynamic world of construction, using lithium carbonate, especially in mortar and other building applications, has been a longstanding practice. However, recent years have seen this material become a subject of concern for various reasons. Its volatile pricing and unpredictable availability pose significant challenges for the industry.

Moreover, environmental and health impacts associated with its extraction and use have raised alarms, leading to a growing demand for safer, more sustainable alternatives. In response to these pressing issues, industry leaders like BASF and Azelis Construction Lab have pioneered innovative solutions that promise to revolutionize how we approach construction materials. Lithium carbonate has been a cornerstone in construction applications due to its beneficial properties in mortar formulations. However, its reliance comes with a host of challenges that can no longer be overlooked. The most pressing of these is the cost factor. Fluctuating prices have always been a concern, but recent trends show an alarming volatility that deeply impacts budgeting and planning in construction projects.

Equally significant are the supply chain issues. With lithium being a finite resource, its extraction and processing have become more complex and expensive, leading to unpredictable supply scenarios. The environmental toll of lithium carbonate production is another critical aspect. Methods like hard rock mining and extracting from underground reservoirs severely strain land and water resources. Additionally, the production process is known to emit significant amounts of carbon dioxide, contributing to the ongoing climate crisis. Health risks associated with lithium carbonate cannot be ignored either. In California, for example, lithium carbonate is listed under Proposition 65 for its potential links to cancer, birth defects, and other reproductive harm. Such concerns have propelled the search for safer, more environmentally friendly alternatives in construction applications.

The collaborative efforts of BASF and Azelis Construction Lab have led to a groundbreaking development in the field of construction materials. By introducing an additive combination that significantly reduces the need for lithium carbonate in cementitious applications, they are setting new standards for sustainability and efficiency in the industry. Chris Hummel, BASF Marketing Manager Building Materials, said "Our goal was to address the growing concerns around lithium carbonate without compromising on the quality and performance that our clients have come to expect. The solution we've developed is not just a workaround; it's a leap forward in construction material technology." Jessica Silva, Laboratory Director for Azelis, followed by stating “We are utilizing the BASF technology to formulate mortars and match the performance criteria to that of a lithium-containing system, to successfully implement the new technology.” This innovative approach focuses on flowable applications like fast-setting self-leveling underlayments (SLUs), which are traditionally dependent on lithium carbonate.

The core of this innovative solution lies in two new polymers: HyCon® R 3660 F and Melflux® SELECT 6030 F, both developed by BASF. HyCon R 3660 F is designed to retard the setting of ternary SLUs that are based on a mixture of calcium aluminate cement (CAC), ordinary Portland cement (OPC), and calcium sulphate. The need for lithium salt accelerators is significantly reduced when used in conjunction with Melflux SELECT 6030 F, which is optimized for plasticization and water reduction. Jisha Hechel, Laboratory Manager of Construction Solutions at Azelis, explains, "The synergy between HyCon R 3660 F and Melflux SELECT 6030 F is remarkable. We can achieve optimal performance while drastically cutting down the use of lithium salts. It's a win-win for both efficiency and sustainability.”

The benefits of this new approach extend beyond just reducing the reliance on lithium carbonate. There are also significant environmental advantages, including the potential for reduced CO2 emissions and less strain on natural resources. In terms of performance, these new additives have shown promising results. "Early strength development and improved cold weather performance are just the tip of the iceberg," noted Hummel. "The ability to achieve faster hardness levels and walk-on times, even surpassing products with higher lithium concentrations, is a game-changer.”

The benefits of this new approach extend beyond just reducing the reliance on lithium carbonate. There are also significant environmental advantages, including the potential for reduced CO2 emissions and less strain on natural resources. In terms of performance, these new additives have shown promising results. "Early strength development and improved cold weather performance are just the tip of the iceberg," noted Hummel. "The ability to achieve faster hardness levels and walk-on times, even surpassing products with higher lithium concentrations, is a game-changer.”

The combined use of HyCon R 3660 F and Melflux SELECT 6030 F introduces a new paradigm in construction material formulation. When used in tandem, these two additives provide enhanced performance characteristics greater than the sum of their individual effects. Hechel elaborated further, "The synergy between HyCon R 3660 F and Melflux SELECT 6030 F is not just about reducing lithium usage. It's about creating a more efficient and robust material. Together, they enable significant improvements in the speed and quality of construction processes."

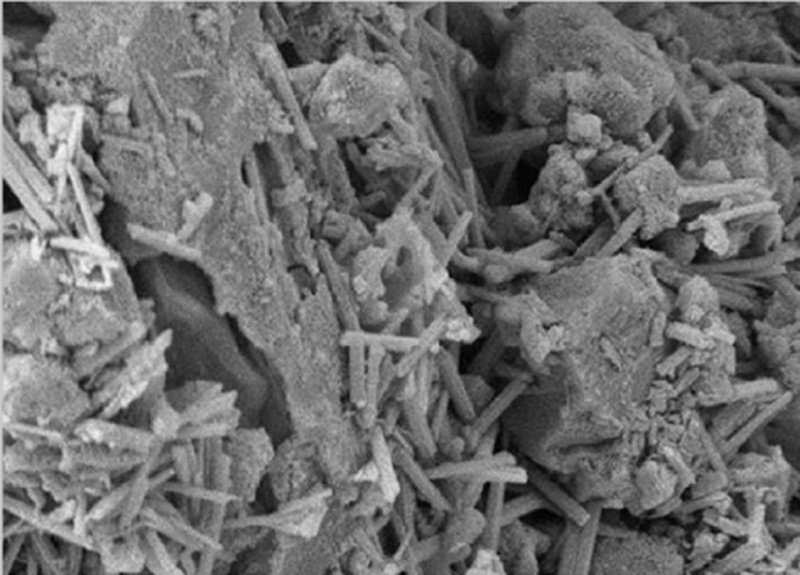

This combination has proven particularly effective in improving early strength development, crucial for projects with tight timelines. Furthermore, the improved cold weather performance, including reduced set times even in extreme temperatures, adds to their versatility in various climatic conditions. One of the critical aspects of these new additives is their impact on the chemical reaction process in construction materials. Specifically, HyCon R 3660 F plays a pivotal role in retarding the setting process of ternary SLUs, which is essential for managing the working time and ensuring a quality finish.

"The retardation effect we achieve with HyCon R 3660 F is finely tuned," Silva said. "It allows for more controlled and predictable setting times, which is vital for large-scale and complex construction tasks."

Melflux SELECT 6030 F complements this by enhancing plasticization and aiding in water reduction, which is crucial for achieving the desired consistency and workability of the mix without accelerating the setting process prematurely. "The retardation in the chemical reaction due to HyCon R 3660 F, balanced with the properties of Melflux SELECT 6030 F, signifies a notable advancement in material science,” Hechel said. “It’s not just about slowing down the reaction; it's about optimizing it for better performance and sustainability.”

One of the most significant advantages of the new additives from BASF and Azelis is their versatility and adaptability to different formulations and customer needs. "Our approach has always been customer centric. We understand that each project has unique requirements, and our additives are designed to be flexible and customizable," Hummel said. Whether it's adjusting stabilizers for specific formulations or tailoring the mixture for unique environmental conditions, these solutions offer a level of customization that sets a new standard in the industry.

The advancements made by BASF and Azelis in developing alternatives to lithium salts represent a significant step forward in sustainable construction practices. By providing solutions that not only address environmental and health concerns but also enhance performance, they are leading the way in material innovation. For those in the construction industry, embracing these new developments could mean more efficient, cost-effective, and environmentally friendly projects. A recent Webinar, “The dilemma of lithium — Cost, health, availability, and sustainability concerns,” provides additional insight on reduced lithium alternatives. You can watch the presentation here.

This technology was developed and is globally marketed by BASF Construction Additives GmbH, which is distributed and technically supported by Azelis in the US and CA.

Contact BASF to learn more about HyCon R 3660 F and Melflux SELECT 6030 F.